NEWS

プロフィール

こんにちは、ロナです。

東京に生まれ、現在は県外を転々としている会社員です。

職場や家庭のストレスで肌荒れ・心の病とどん底だった私・・・

今では幸せを感じる毎日を過ごしています。

世の中で同じように疲れ切った方々に届けたい

『Make Up』ではなく『Clean Up』を

Exercise

- ヨガ

- 散歩

- 有酸素

- 筋トレ

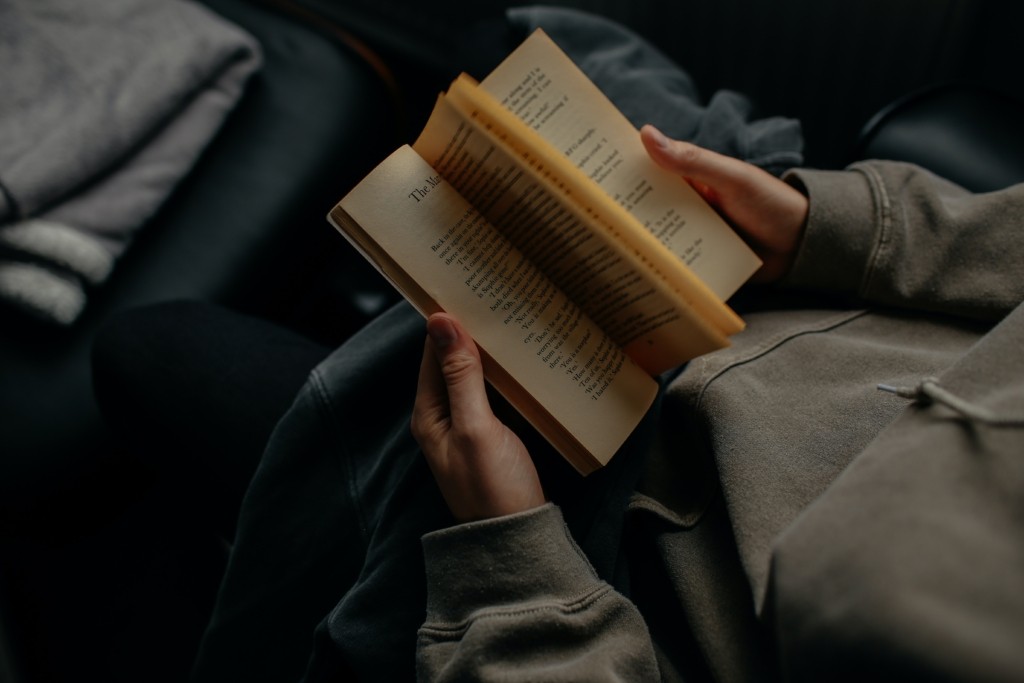

Book

- マインドセット

- スピリチュアル

- 自己啓発

Food

- Breakfast

- Lunch

- Dinner

- Snack

こんにちは、ロナです。

東京に生まれ、現在は県外を転々としている会社員です。

職場や家庭のストレスで肌荒れ・心の病とどん底だった私・・・

今では幸せを感じる毎日を過ごしています。

世の中で同じように疲れ切った方々に届けたい

『Make Up』ではなく『Clean Up』を